July

The second half of the year began with Himself starting work on the very final scenic board of the layout which leads into the fiddle yard at the southern (Aberglaslyn) end of the layout.

In a matter of a few days it had progressed from bare Mod Roc to the top coat of plaster and walls and grass being added.

While that was going on I was working on a 5th SAR / WHR wagon kit, this time for the V-16 brake van.

This shot shows one of the masters for the sides made out of styrene with the waterslide rivet transfers being added.

August

Although we had now built all the scenic boards which make up the complete layout the fiddle yards at the back were still outstanding.

With just a few weeks to go until the exhibition in Woking Himself got down to work designing and constructing them.

He was also starting to add some of the finer details on the other parts of the layout like these complex gates around one of the farm crossings.

They were all made up from styrene strips.

I was also making up more of my resin wagon kits for clients who wanted them ready to run.

This is a pair of NGY ballast wagons.

September

For the first time in a while I was able to start work on a model for the layout, having spent a number of months fulfilling an agreement with a client for a rake of wagon kits.

The subject was the WHR's latest carriage produced at Boston Lodge, 2046.

Here are the major component parts fabricated from styrene before it was assembled into a body shell.

On the layout, Himself had painted the two new houses I made earlier in the year and fixed them in position in the estate scene just south of the station.

As you can see there are many more houses still til be designed and made...

And so finally, towards the end of the month, the big reveal!

Bron Hebog made its debut as a complete (but not finished!) layout at the exhibtion in Woking.

Take a look back through the blog to find more pictures from that weekend.

October

I didn't get to join the team at the exhibition and would have to wait until Hull in November for my first glimpse of the completed layout.

By this time I'd more or less finished my model of 2046.

My next project was something which had been on the To Do list for many years - the Match Wagon which carries the tools for the KMX Tamper.

The basis for the model was a OO9 Society kit for ex RNAD wagons which had a new superstructure built out of styrene on top of the chassis from the kit.

It took it with me on a visit home to set the height of the coupling against those on the Tamper.

I also carried with me a 2nd model of the KMX which I'd been slowly building over the last couple for years for a client who was involved in re-engineering the machine for the WHR.

I couldn't resit the chance to photograph the two of them together.

November

The main focus on the layout was completing some of the finer scenic details such as the livestock grids which protect the many level crossings around the layout.

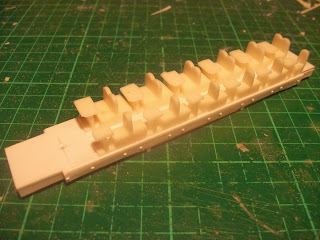

Unable to find some styrene sections of the right profile for the job I ended up casting many dozens of lengths of section out of resin.

This is just one half of one crossing - there are many more to go...

And so to the exhibition in Hull...

Once again there are lots more pictures elsewhere on the blog if you want to go looking for them.

December

So in the last few weeks of the year I've been working on another carriage, this time the brand new updated design of Super Barn 119 which has recently entered service on the FR.

The word is there will be more of these emerging from the carriage works at Boston Lodge very soon so I've taken the precaution of making masters and casting this one in resin in the expectation it will be easier to make subsequent ones.

If the FR alters the design in the meantime there will be trouble!

The shape and arrangement of the windows are the major change from the original 3 Super Barns so I was able to use my castings for the seats and tables from the earlier carriages with no problems.

And currently Himself has started work on the backlog of incomplete carriages which has built up over the last couple of years while he's been concentrating on locomotives and the layout.

So there are the highlights of our modelling during 2014. Many thanks for visiting the blog and taking a look at what we're up to, we hope you'll stick with us and maybe come along and see us out on the road in 2015.

Happy New Year.

.jpg)